A Dictabelt Machine

|

|

'Dictabelts' were a sound recording format intended for use in offices. The recording material was an endless plastics belt about 3 .5 inches wide and 12 inches circumference. It was mechanically recorded by an engraving process and replayed with a stylus similar to that of a microgroove record player. During operation, the belt was tensioned around a pair of drive rollers, which could then be slackened to allow its removal.

The great advantge of these belts was that they could be flattened and slipped into an envelope for postage and would normally remain sufficiently uncreased to allow playback. When stored for long periods of time, the creases tended to become permanent and deterioration of the plastics material could lead to embrittlement. Belts in this condition would, at best, throw the replay stylus out of the groove at each revolution and at worst would split and become unplayable. The Mandela Dictabelts were beginning to suffer from these problems.

REPLAY SPEED

I had been warned in advance by Peter Copeland of the British Library

National Sound Archive that these belts appeared to have been

recorded at a slower speed than usual. The first attempts at replay

were made on a 'normal' Dictabelt machine, from which the sound came

out at more than double speed.

To slow the sound down, it was first recorded at 15 ips on a Ferrograph Logic 7 tape recorder and then replayed at 7.5 ips with a variable frequency mains drive to the Ferrograph's motors for fine speed adjustment. The resulting replay was satisfactory but grooves which had been lost because of stylus jumps could not be easily heard or corrected when listening to the double-speed sound direct from the Dictabelt. They only showed up after the speed had been reduced and then it was difficult to locate and replay the missing Dictabelt segments.

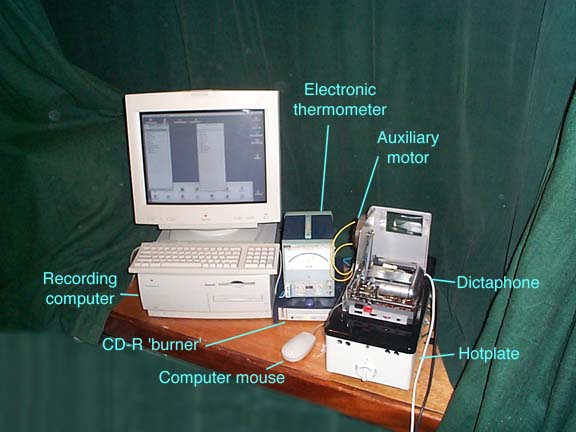

For this reason, the Dictaphone machine needed to slowed down before a transfer was made; the machine's own motor was unsuitable for variable speed operation, so an auxilliary motor and drive belt was fitted to allow this to be done.

The Dictabelts were placed on the rollers of the Dictabelt machine which was driven by a flat rubber belt from an external motor mounted above the mechanism on an aluminium plate. To avoid the Dictabelts splitting and to flatten out the creases which had set over the years, the whole machine, with its Dictabelt, needed to be operated at an elevated temperature.

REPLAY TEMPERATURE

The heat was provided by standing the Dictaphone on an industrial

hotplate. The energy controller fitted to the hotplate was too coarse

for this application, so it was manually controlled in response to

the readings of an electronic thermometer . The thermometer monitored

the temperature of the system from a thermocouple mounted on the

frame of the back roller (under the adhesive patch at the end of the

blue wire). That part of the frame is enclosed by the Dictabelt in

normal operation and its temperature is reasonably representative of

Dictabelt temperature. The hotplate was manually switched on and off

as required.

The electronics of the Dictaphone will not function correctly at

elevated temperatures, so a connection was brought out from the

playback cartridge to an external amplifier and frequency-response

correction equipment. The wire for this is visible looping upwards

from the playback carriage at the top front of the machine. The

traversing slidebars and the leadscrew which drives the carriage can

be seen near the front of the machine, parallel to the rollers.

The machine was operated with all covers open or removed so as to

give easy access to the belt and mechanism for adjustment and to

allow manual guidance of the playback stylus when necessary.

SPEED CONTROL

The motor speed is related to the frequency of the A.C. power supply.

To allow this to be varied, a sinewave voltage from a signal

generator was amplified by a pair of Quad 50E audio amplifiers.

These amplifiers can give up to 100 volts rms output; so by

connecting two of them in series, a 200 volt variable-frequency

supply was available to operate the motor over a range of speeds.

Low levels of recorded mains hum were found on the Dictabelts and this could be detected by a sharply-tuned electronic filter and displayed on an oscilloscope. By comparing this hum with the frequency of the local mains supply during playback (and assuming the mains supply during recording was of the same frequency), the playback speed could be monitored and manually adjusted to the correct value by varying the motor supply oscillator frequency.

The sound was amplified and corrected for frequency response, then digitised and recorded on the hard disk of an Apple Mac G3 computer. On this, any remaining groove-jumps and the belt changes could be edited out before the reconstructed sound was recorded onto CD-Rs.

Larger versions of the photographs on this page are available by clicking on the captions.

Poppy Records offers a Dictabelt transcription service

Text: ©2001 Liz Tuddenham

Photographs: © 2001 R.N. Davis

All trade marks acknowledged.