RECORDGRAPH

A sound recording and reproducing system

Recordgraph Film Recorder

By W. L. Woolf

Recordgraph Corporation

Recordgraph Film Recorder

By W. L. Woolf

Recordgraph Corporation

The use of motion picture film for sound recording has long offered the alluring promise of a phonographic sound record of many hours duration without the necessity of changing a record, at prices per hour of recording far below any achieved in disc recording of the conventional phonograph type.

The introduction of a recording instrument profiting by these natural advantages has been delayed by a number of practical problems of such hardihood as to tax both the genius and staying powers of recording engineers. The cellulose nitrate film, for instance, is an ideal recording medium but highly inflammable and therefore unsuitable as a material to be handled by the public. The cellulose acetate or safety film, on the other hand, while as safe to handle as paper, has a cellular structure which responds to a cutting stylus much like a good grade of ocean sand and looks as much under the microscope, leaving a sound track with a noise to signal ratio, like the Mountain to Mohammed. With cutting ruled out as a recording method, burnishing was tried. Fortunately, burnishing, if done at sufficiently high pressure, leaves a smooth, hard, compressed sound track of unbelievable durability and a noise level made conspicuous by its almost complete absence, especially vhen compared with the noise level of commercially pressed phonograph records.

In burnishing at high needle pressures, however, particularly at low and consequently economical film speeds, the film offers a mechanical impedance of such magnitude as to render all conventional recording heads totally useless. The impedance offered at the stylus point is so high that in rubber damped recording heads the film modulates the rubber rather than vice versa and delicate heads of low inertia and good frequency characteristics designed for cutting wax or nitrate coated records simply break into chattering nodes under the resistance to modulation offered by the acetate film.

With a satisfactory recording head finally designed. there remained other. problems of dragon proportions to test the steel of the engineering St. Georges. Vibration, a bugbear in all motor driven sound machines, had to be tamed. Easy threading had to be achieved, Convenient and simplified operation was essential, automatic shifting from one track to the next was imperative, a machine must operate over long periods without film breakage or dangerous temperature rise, suitable indexing facilities must be provided as well as means for quickly finding and replaying any portion of a long time record, and for continuous operation a suitable film splice must be developed.

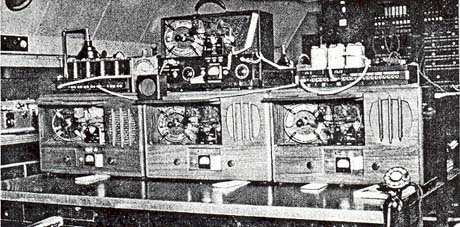

These problems have all been faced squarely in a new instrument manufactured by the Recordgraph Corporation of New York City. Several models of these instruments are now in test operation in the New York and Washington offices of the National Broadcasting Company, where they are used to provide a continuous and permanent record of the programs of the Red and Blue Networks. These machines are of the continuous type, operate eighteen hours per day, require very little supervision and only necessitate a change of film every six hours. A battery of four continuous recorders is shown in photograph number one.

The Recordgraph Corporation supplies these Instruments in either portable or stationary types or for rack mounting in racks of conventional width.

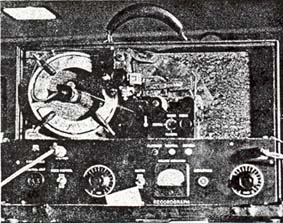

In these instruments 35 mm. film is used as the recording medium. The space between the perforations is used to record 100 sound tracks. The film is propelled at either 20 ft. or 40 ft. per minute. At the former speed, 61/2 ft. of film per hour are consumed, both sides of the film being utilized, At this speed the sound recording may be described as telephone quality, the upper frequency cut-off being in the neighborhood of 3,Q00 cycles pcr second. At 40 ft. per minute, the freqvency response is increased to 5,000 cycles per second. At this speed l21/2 ft. of film are consumed per hour. The cost of film suitably packaged and ready for use is 183/4c per hour for the slow speed and double that for the high speed recording. Details of one of these machines is shown in the photograph which is a semi-closeup of a portable model.

Mechanical Fundamentals

Fundamentally the instrument consists of a drive sprocket mounted on a spindle provided with a motor driven flywheel. The, sprocket draws the film over a recording drum on which rests the point of the recording stylus under control of the recording head which is energized by the signal output of a suitable amplifier. The recording stylus impresses a laterally modulated sound groove in the film suitable for playback with a conventional electrical pickup.

The film is an endless loop. Each time it makes a complete revolution the recording stylus is automatically moved laterally through an oblique angle to the succeeding sound track. The recording may thus be continued until one hundred tracks have been made on the film, at which time the instrument automatically stops.

In operation the instrument is first threaded with a suitable roll of film, The manufacturer supplies the film in rolls of appropriate lengths for various playing periods ready for immiediate use. At the factory the appropriate number of turns is wound on a roll of the correct size and the two ends of the film are spliced together, leaving however, a loop of proper length external to the concentric layers of the roll. The film is then provided with a metal contact for closing an electric circuit, treated to reduce surface noise and packed with a blank log for indexing the track number of various parts of the program to be recorded. To thread the film the operator simply places the roll over the film magazine, like putting a hoop over a barrel and threads the loop over the recording drum under a safety switch and over the sprocket. One end of the loop comes from the inside of the roll, passes over the drum and sprocket and back to the outside of the roll.

With the exception of the starting switch, tone and volume control, all other operations of the instrument are accomplished with a single four position knob. By turning the knob in one position the instrument may be threaded as above described. In the next position the instrument is ready to record, in the third position, to playback, and in the fourth, marked "neutral," both recording and reproducing styli are removed from the film. In this position the amplification system composed of a microphone, amplifier and loud speaker are connected for public address use. A red light indicates when the instrument is in the "record" position, a green light in "playback," and a white light in "neutral." A meter indicates the output volume permitting the operator to set the volume control at the volume desired.

With the instrument in recording position, recording is commenced. By means of a switch the driving motor is turned on which drives the sprocket, thus propelling the film. A sound track is recorded once around the film, at which time the metal contact attached to the film, closes an electric circuit, starting a small carriage motor which rotates a worm geared to the recording head carriage thus moving the recording head laterally the distance of one sound track, At this point a pawl drops into a notch in a disc attached to the worm simultaneously stopping the lateral movement of the recording head and breaking the carriage motor circuit. During the first round of the film there has been recorded thereon a track parallel thereto. That portion of the sound track recorded while the carriage motor is in motion is made at a small angle obliquely crossing the film. The major portion of each sound track therefore is parallel with the film and a short portion is at a small oblique angle running into the next succeeding track. The sound track is continuous from the start of the first track to the end of the last one.

A counting device indicates at all times the track being recorded or played back, and the operator, while recording, makes an index, jotting down the track number on a log blank supplied with the film on which each selection is to be found.

The recording drum on which recording is accomplished provides a highly polished and hardened revolving recording floor. The point of the sapphire recording stylus is approximately .002 inches in diameter and records a track between .002 and .003 inches in depth. Unemulsified leaderstock, .008 inches thick, provides adequate body to permit recording on both sides. A sapphire needle is also employed for playback. Since both recording and reproducing styli are raised and lowered by a knob provided with a reduction gear, the styli are both lifted and set down gently, reducing breakage practically to the vanishing point and thus permitting the needles to be permanently set at the factory. In this manner the most advantageous angle is permanently obtained, no material is cut from the surface of the record which has to be disposed of, no needle requires sharpening or change and consequently the conditions of recording are fixed permitting the operator to obtain good results with a minimum of variables and rehearsals.

The instrument is driven by an alternating current fractional horsepower motor deeply mounted in felt and rubber to isolate motor vibration from both the flywheel, which is rubber driven, and the frame. The power switch with which the motor is started is provided with a cam which relieves the pressure of the motor pulley against the rubber idler when the switch is turned off, thus preventing deformation of the idler when not in use.

Film breakage in this instrument has been reduced to a point below that anticipated in motion picture practice. No projecting lamp is present to dry and weaken the film and intermittent motion, which plays havoc with the perforations in motion picture practice, is absent in the recording instrument. Should the film break, however, there is provided a switch which automatically stops the drive motor, preventing damage to the film.

The recording head is of the magnetic type. The rigidity of the stylus is much greater than that of the conventional recording head In order to properly match the mechanical impedance of the head to the mechanical impedance offered by the film in the process of burnishing, particularly at iow speed. Two independent sets of restoring springs hold the recording stylus in its normal unstressed position. One set is applied to the vibrating armature and one set to the stylus. A light metal drive rod connects the armature to the stylus. This structure makes the stylus extremely rigid. In several years' use it has never been necessary to adjust, retune or rebuild a recording head. It has been successfully used while operating in the rear seat of an automobile over miles of rough road. The recording head consumes slightly less than one watt of power in normal recording. The pressure of the recording stylus at the recording point approximates 70,000 pounds per square inch.

At this pressure the material becomes plastic flowing around the needle and leaving a compressed, highly polished sound track capable of hundreds of playings without appreciable deterioration and of low noise level.

The outstanding features of this instrument are the long-time recording periods achievable without interruption or changing the film, the small storage space required per hour of recording, low cost of recording medium, permanency of the record and the great stability of the recording instrument. The double spring system of the cutting head, which would be impractical for recording by other methods, but ideal for burnishing on acetate, results in a stability under rough handling not even remotely achieved in any other recording head. The rounded, polished burnishing point of the recording needle possesses a reliability and freedom from attention that can never be achieved by a cutting needle which must be constantly sharpened or changed under the eye of a highly trained technician. The hardened and polished recording and reproducing floors operate for years without wear or attention as compared to the constant attention required by soft or absorbent materials. The native toughness and pliability of the safety acetate film into which is compressed a dense, hardened, polished and toughened sound track, permits hundreds of playings with only a very small fraction of the wear suffered by other records.

S.T.C Journal &emdash; January 1941